Construction projects demand both speed and quality. Workers need to finish tasks quickly without sacrificing the strength or durability of the materials. A hydraulic concrete mixer helps achieve both goals.

This type of mixer improves efficiency and ensures consistent concrete quality. It is a valuable tool for many kinds of building and repair jobs. This article explains how it works and why it matters.

What Is a Hydraulic Concrete Mixer?

A hydraulic concrete mixer uses hydraulic power to mix concrete. This system provides smooth and reliable operation. It allows for better control during the mixing process.

These mixers are known for their efficiency and durability. They can handle different types of concrete mixes with ease. That makes them useful for a wide range of construction tasks.

Hydraulic systems also reduce the strain on the machine. This leads to less wear and tear over time. The result is a longer-lasting and more dependable mixer.

How It Boosts Productivity

Productivity is important on any job site. A hydraulic concrete mixer helps workers mix concrete faster and more efficiently. That speeds up the overall construction process.

The hydraulic system allows for quick and smooth mixing. Workers spend less time waiting and more time pouring or finishing. This helps keep the project on schedule.

These mixers can handle larger batches compared to manual or basic electric models. That reduces the number of mixes needed for big projects. Less downtime means more work gets done.

Operators also find hydraulic mixers easy to use. Simple controls and consistent performance help reduce errors. That leads to fewer delays and better workflow.

Maintaining High-Quality Results

Quality is just as important as speed. A hydraulic concrete mixer ensures consistent mixing results every time. That leads to stronger and more durable concrete.

The hydraulic system provides even mixing. This helps distribute materials uniformly throughout the mix. The result is a better final product with fewer weak spots.

Workers can also adjust the mix easily. That means they can meet the exact requirements for different parts of a project. Consistency across the job helps maintain high standards.

These mixers are suitable for a variety of concrete types. Whether you need foundation mix or paving concrete, the quality remains high. That flexibility is valuable on any job site.

Benefits for Different Project Types

Hydraulic concrete mixers work well for many types of projects. They are useful for building foundations, walls, and floors. They also support roadwork, repairs, and landscaping.

For contractors, these mixers improve job site efficiency. Workers can mix concrete as needed, without delays. That helps complete projects faster and within budget.

Homeowners and small builders also benefit. A hydraulic mixer can handle small to medium jobs with ease. It offers a good balance of performance and value.

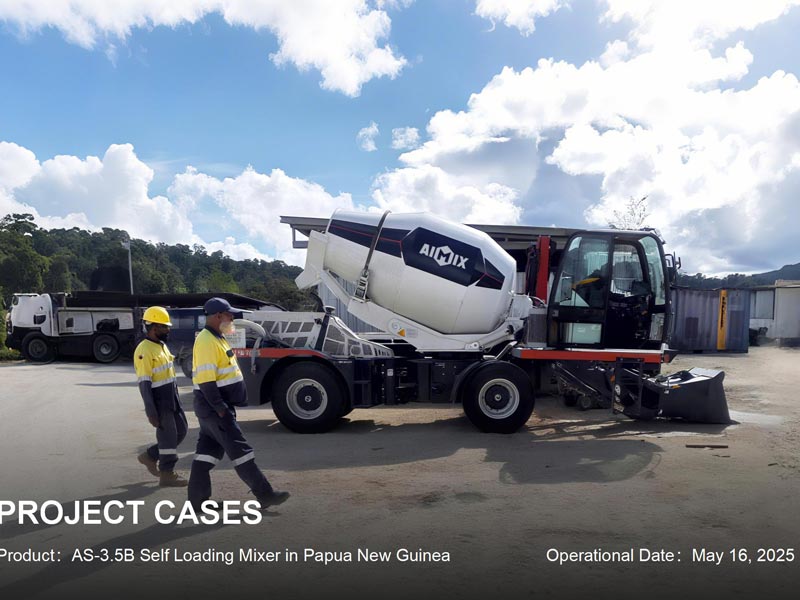

Self Loading Mixer Concrete: A Complementary Option

For even more efficiency, some workers use a self loading mixer concrete. This type of mixer loads, mixes, and discharges concrete automatically.

When combined with a hydraulic system, productivity increases even more. Workers save time on loading and mixing. That leads to faster project turnaround without losing quality.

Both types of mixers ensure consistent results. They help contractors and builders meet deadlines while maintaining strong concrete standards.

Conclusion

A hydraulic concrete mixer boosts productivity without sacrificing quality. It mixes concrete quickly, evenly, and reliably. That helps workers finish projects faster and better.

Whether you use a hydraulic mixer alone or with a self loading mixer concrete, the results are clear. You get more done in less time, with stronger and more durable outcomes.