Multifunctional concrete mixers are revolutionizing job site efficiency. They help complete projects faster while reducing costs. Let’s explore how these mixers deliver such impressive results.

We will focus on self-loading and mobile concrete mixers. These machines are key to saving time and money. Let’s begin with the basics.

The Need for Efficient Concrete Mixing

Construction projects often face tight deadlines. Traditional concrete mixing methods can be slow. They require multiple machines and extra labor. This increases project costs and delays.

Multifunctional concrete mixers solve these problems. They combine multiple functions in one machine. This efficiency helps complete projects faster and cheaper.

These mixers are designed to handle various tasks. They can mix, transport, and discharge concrete efficiently. This versatility is crucial for modern construction.

Self-Loading Concrete Mixers: Saving Time and Labor

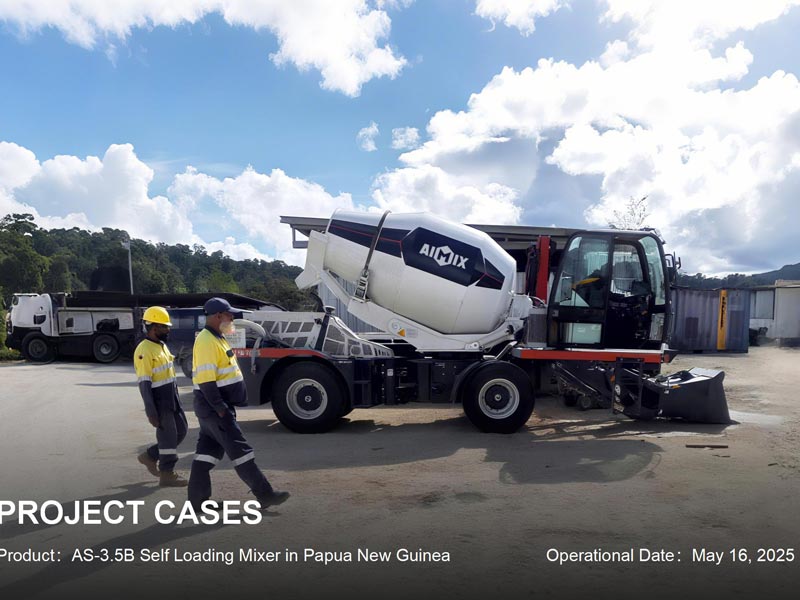

The self-loading concrete mixer for sale is a major time-saver. It can load materials automatically without extra help. This feature reduces the need for manual labor.

These mixers can load sand, gravel, and cement in one step. They simplify the mixing process and save valuable time. Workers can focus on other tasks while the mixer operates.

Self-loading mixers are ideal for remote job sites. They can operate independently without additional equipment. This independence reduces transportation needs and costs.

Mobile Concrete Mixers: Flexibility and Efficiency

Mobile concrete mixers offer great flexibility on job sites. They can be moved easily between different locations. This mobility ensures concrete is available wherever it’s needed.

These mobile concrete mixers for sale reduce the need for long-distance transportation. They mix concrete on-site, saving time and fuel costs. Mobile mixers are perfect for dynamic construction environments.

Mobile mixers can handle various project sizes. They are suitable for small repairs and large-scale projects. This adaptability makes them valuable for different construction needs.

Cost Savings with Multifunctional Mixers

Multifunctional concrete mixers reduce overall project costs. They eliminate the need for multiple machines. This reduction in equipment lowers operational expenses.

These concrete mixers also minimize material waste. They produce only the required amount of concrete. This efficiency saves money on materials and disposal.

The time saved by using multifunctional mixers translates to lower labor costs. Projects are completed faster, reducing workforce needs. This efficiency is crucial for budget-conscious projects.

Conclusion: A Smart Investment for Job Sites

Multifunctional concrete mixers are a smart investment. They slash job site time and costs through efficiency. Self-loading and mobile models offer unique benefits.

These mixers streamline construction processes and reduce expenses. They are essential tools for modern job sites. Investing in multifunctional mixers leads to successful projects.