When Indonesian contractors plan to invest in an asphalt plant, one of the first questions they ask is: “How does the asphalt plant’s production capacity influence its purchase asphalt mixing plant price?” Understanding this relationship helps contractors make informed decisions, avoid over-investing, and optimize project costs. In this article, we explore the key factors that link production capacity to purchase price and provide practical insights for contractors operating across Indonesia.

Understanding Asphalt Plant Capacity

Production capacity refers to the amount of asphalt a plant can produce per hour, usually measured in tons per hour (TPH). For small to medium projects in Indonesia, asphalt plants commonly range from 20 TPH to 80 TPH. Choosing the right capacity ensures efficient project execution without unnecessary expenses.

For instance, a 20 TPH aspal mixing plant is suitable for road maintenance or small urban projects, while a 50–80 TPH plant serves larger highway or commercial projects. This range allows contractors to match production capabilities with project requirements, avoiding both underutilization and overcapacity.

How Production Capacity Drives Purchase Price

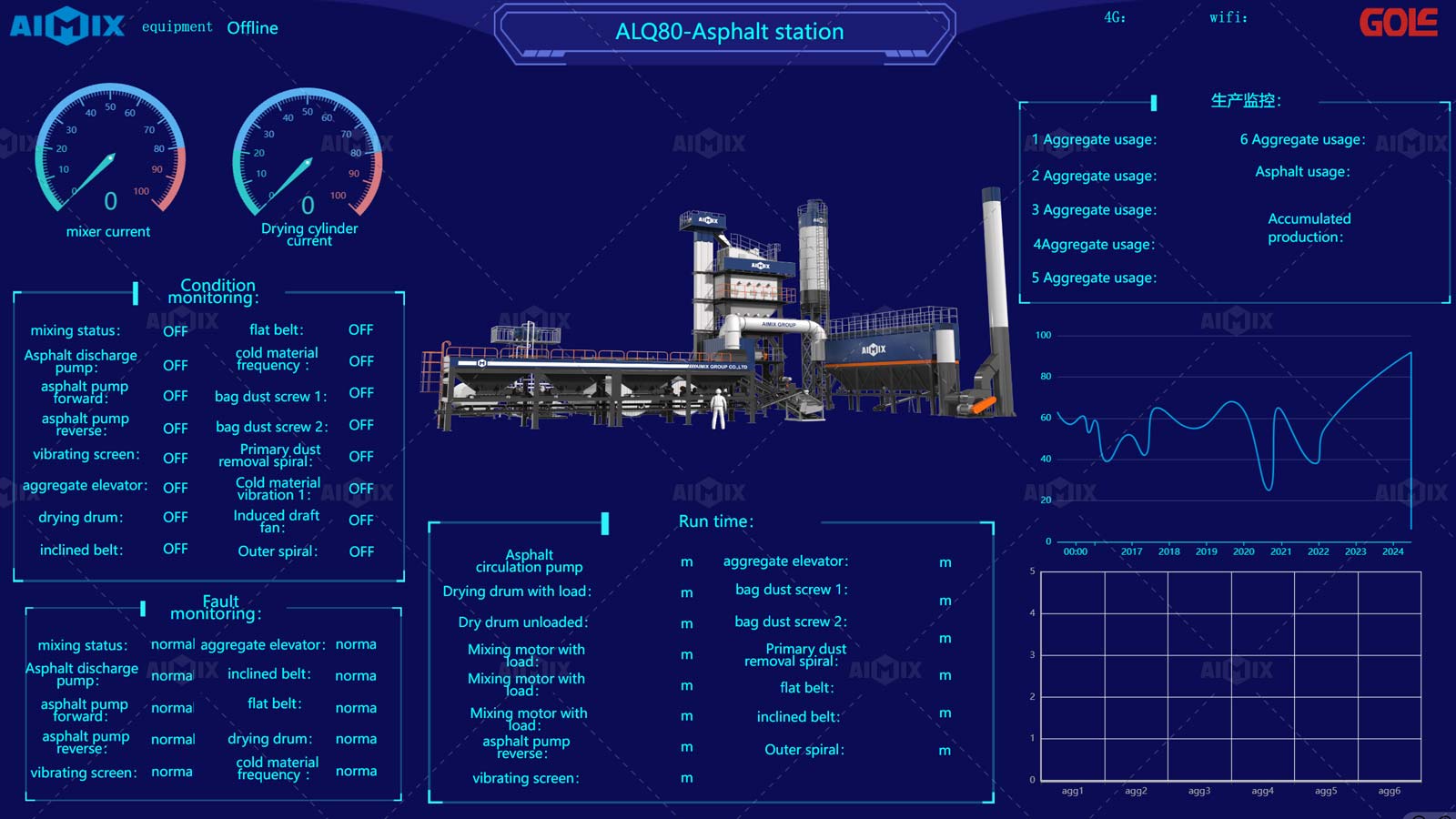

The purchase price of an asphalt plant rises with its production capacity. Larger plants require more robust components, stronger mixers, bigger burners, and more advanced control systems. Additionally, higher-capacity plants often include enhanced automation and monitoring systems to ensure consistent output quality.

For example, a 20 TPH plant may cost significantly less than a 50 TPH plant due to differences in mixer size, fuel efficiency, and structural design. Similarly, a 50 TPH plant is more affordable than an 80 TPH plant, but it comes with higher output potential, which can save money in the long term if projects demand large volumes.

Cost vs. Project Efficiency

Investing in a higher-capacity plant increases upfront costs, but it also improves project efficiency. Contractors can produce more asphalt in less time, reducing labor costs and minimizing downtime. Conversely, selecting a plant with too low a capacity may lead to frequent batch shortages, delaying project timelines and increasing operational costs.

Therefore, contractors must weigh the trade-off between purchase price and production efficiency. A 50 TPH plant might have a moderate purchase price while offering sufficient output for medium-scale projects. This balance is particularly important in Indonesia, where construction projects often face logistical challenges across islands and remote locations.

Other Factors Influencing Purchase Price

While production capacity plays a major role, other factors also affect the price:

- Automation Level: Advanced control systems and PLC touchscreens raise the price but reduce labor dependency.

- Mobility: Mobile asphalt plants are generally pricier than stationary ones due to flexibility and transport capabilities.

- Fuel Type and Efficiency: Plants designed for low fuel consumption may cost more initially but save money in operation.

- Additional Features: Dust collection systems, hot oil heaters, and remote monitoring increase both efficiency and purchase price.

Each factor interacts with production capacity. For instance, a high-capacity plant with low automation may cost less than a medium-capacity plant with full automation.

Tips for Indonesian Contractors

To choose the right asphalt mixing plant mini:

- Assess your average project size and required asphalt volume.

- Consider transportation distances between islands or remote sites.

- Balance upfront investment against long-term operational savings.

- Request detailed quotations including optional features and maintenance costs.

Taking these steps ensures you select a plant that fits both your budget and project needs.

Conclusion: Make Capacity Work for You

Production capacity directly influences the purchase price of 20–80 TPH asphalt plants. Choosing the right capacity can save money, improve efficiency, and streamline project timelines. Indonesian contractors should carefully analyze project requirements, operational logistics, and plant features before making a purchase. By doing so, they ensure maximum value from their investment.

At AIMIX, we provide a range of asphalt plants tailored for Indonesian conditions, from 20 TPH for small urban projects to 80 TPH for large-scale highways. Our plants combine reliability, efficiency, and cost-effectiveness, helping contractors achieve project goals with minimal hassle. Contact us today to find the asphalt plant that fits your capacity needs and budget.

More articles about asphalt plant: https://aimixconcretesolution.blogrip.com/2025/08/13/mini-asphalt-plant-choice-for-producing-400-tons-of-asphalt-in-rainy-season-projects/