Road repair projects, whether urban streets, highways, or rural roads, require reliable and efficient concrete production to ensure long-lasting results. In this context, a small concrete batching plant offers a range of advantages for contractors and municipal authorities alike. Compared to large-scale plants, small plants are flexible, cost-effective, and easy to deploy on short-term projects. When combined with modern batching plant equipment, these small plants can provide consistent quality and efficiency for road repair operations.

What is a Small Concrete Batching Plant?

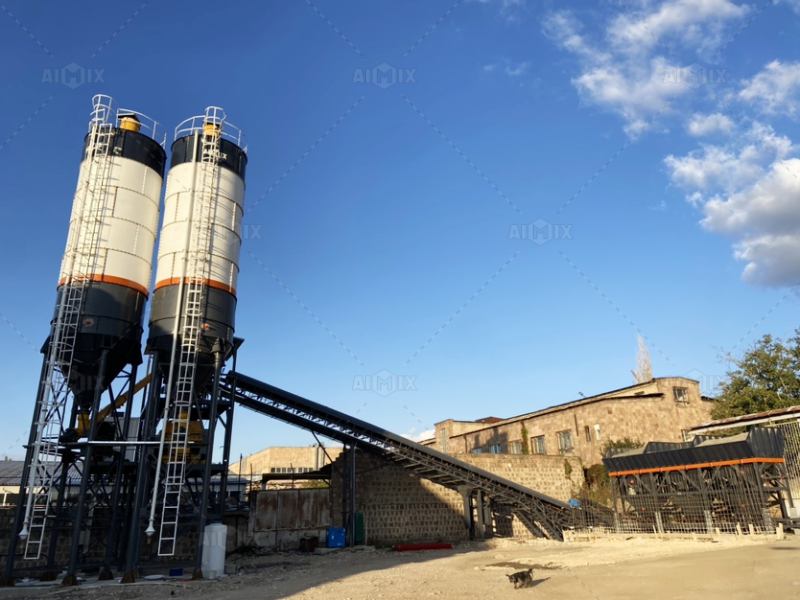

A small concrete batching plant is a compact facility designed to produce concrete in smaller volumes than traditional large plants. These plants typically include components such as:

-

Aggregate storage bins

-

Cement silos

-

Weighing systems for precise material measurement

-

Mixing equipment (pan or twin-shaft mixers)

-

Control systems for automated or semi-automated operations

With the right batching plant equipment, small concrete plants can deliver consistent concrete mixes, meeting both local and national standards for road construction and repair.

Advantages in Road Repair Projects

Quick Installation and Flexibility

One of the main benefits of a small concrete batching plant is its ease of setup. Many models are designed for rapid deployment, making them ideal for temporary or short-term road repair projects. Unlike large, stationary plants, small plants can be transported to different sites and assembled in a short time, reducing downtime and speeding up project completion.

This flexibility is particularly valuable in urban areas, where road closures must be minimized, and repairs need to be completed quickly. Mobile units within the small batching plant category allow contractors to relocate the plant as the project progresses.

Cost-Effective Solution

Small concrete batching plants require lower initial investment compared to large-scale plants. Operational costs, including labor, energy, and maintenance, are also reduced. For road repair projects, where concrete volumes are moderate and the project duration is limited, a small plant ensures that resources are not wasted on overproduction.

With efficient batching plant equipment, such as automated weighing and mixing systems, the plant minimizes material waste, ensuring cost efficiency while maintaining consistent concrete quality.

Consistent Concrete Quality

Road repair requires concrete that meets specific strength, durability, and finish standards. Small concrete batching plants, equipped with modern batching plant equipment, can produce uniform mixes with precise aggregate, cement, and water ratios.

Features like automated control systems, real-time monitoring, and precise weighing allow contractors to maintain high-quality concrete, reducing the risk of cracks, shrinkage, or premature wear on the repaired road sections.

Compact Footprint

Space is often limited in road repair projects, especially in urban or congested areas. Small concrete batching plants occupy less space, making them suitable for installation alongside the repair site without causing obstruction. This compact design also simplifies logistics for material delivery, storage, and plant operation.

Energy Efficiency

Modern small concrete batching plants are designed to be energy-efficient. The use of high-efficiency mixers, conveyors, and control systems ensures that electricity consumption is minimized. By optimizing energy usage, contractors can reduce both operational costs and the environmental impact of road repair projects.

Ease of Maintenance and Operation

A small concrete batching plant with well-designed batching plant equipment is easy to operate, even for teams with limited experience. Maintenance routines are simpler and less costly compared to large plants, as components are easily accessible and spare parts are more readily available.

Regular maintenance ensures the plant continues to produce high-quality concrete without interruption, which is crucial for road repair projects with tight deadlines.

Scalability and Modular Design

Many small concrete batching plants are modular, meaning additional units or equipment can be added as project requirements change. For example, extra aggregate bins or additional mixing units can increase production capacity temporarily. This modularity allows contractors to scale operations without investing in a completely new plant.

Environmental Benefits

By producing concrete near the road repair site, small concrete batching plants reduce the need for long-distance concrete transportation, lowering fuel consumption and greenhouse gas emissions. Additionally, advanced batching plant equipment often incorporates dust suppression systems and efficient material handling, contributing to cleaner, greener operations.

Real-World Applications

Small concrete batching plants are increasingly used in a variety of road repair scenarios:

-

Urban street maintenance: Quick setup and compact size allow operations without significant traffic disruption.

-

Highway patching: High-quality concrete produced on-site ensures smooth, durable repairs.

-

Rural road rehabilitation: Mobile plants enable concrete production even in remote locations with limited infrastructure.

-

Emergency repairs: Rapid deployment of small plants allows immediate response to damaged roads caused by weather, accidents, or natural disasters.

By leveraging modern batching plant equipment, these small plants can efficiently meet the concrete demands of diverse road repair projects.

Conclusion

For road repair projects, a small concrete batching plant offers unmatched flexibility, efficiency, and cost-effectiveness. With compact design, rapid deployment, and modern batching plant equipment, these plants ensure consistent concrete quality while reducing operational costs and environmental impact.

Whether the project involves urban streets, highways, or remote rural roads, small concrete batching plants provide a practical solution that balances production capacity, quality, and mobility. Contractors and municipal authorities increasingly rely on these plants to complete road repairs on time, within budget, and to a high standard of durability.