In today’s construction industry, choosing the right asphalt mixer plant can make a huge difference in project efficiency and cost savings. For companies aiming to produce between 1,000 and 2,000 tons of asphalt per month, selecting tarmac asphalt plants that balance productivity, energy efficiency, and operational flexibility is critical. This guide helps you identify cost-effective options while considering practical global use scenarios.

Understanding Your Asphalt Production Needs

Before investing in any equipment, it is essential to define your production requirements clearly. Producing 1,000–2,000 tons per month typically suits small to medium-sized construction projects, such as regional road maintenance, airport runways, and urban paving tasks. By understanding these needs, you can avoid overspending on high-capacity plants that exceed your actual demand.

Project Scale and Frequency

For monthly production under 2,000 tons, frequent batching is necessary. Plants with fast mixing cycles reduce downtime and ensure consistent output. Additionally, consider whether your projects are continuous or intermittent. Plants with flexible operation modes allow you to adjust production without compromising asphalt quality.

Material and Energy Efficiency

Cost-effectiveness is not just about upfront investment—it also depends on operational costs. Efficient fuel usage, precise aggregate heating, and minimized asphalt waste can significantly reduce monthly expenses. Plants equipped with modern burners and automated control systems often save 10–20% in energy costs compared to traditional models, directly impacting your bottom line.

Comparing Asphalt Mixer Plant Types

Asphalt plants generally fall into two categories: batch mix and drum mix. Both have advantages depending on your production and project requirements. Understanding their differences helps you choose the most economical option for your situation.

Batch Mix Plants

Batch mix plants produce asphalt in discrete batches. This allows precise control over mix quality and composition. For projects requiring multiple asphalt types, batch plants are ideal. The batch mix asphalt plant can provide flexibility, ensuring you meet specific project standards without overproducing or wasting materials.

Drum Mix Plants

Drum mix plants operate continuously, producing asphalt non-stop. They often have a lower initial cost and simpler structure. For steady, medium-volume production of 1,000–2,000 tons monthly, a compact drum mix plant can be highly cost-effective. Its continuous operation reduces labor requirements and ensures uniform material heating, enhancing consistency.

Global Cost Considerations

When choosing a plant globally, factor in shipping costs, installation, and local service availability. Plants with modular designs simplify transport and setup in remote locations. Moreover, considering plants with local support networks ensures quick maintenance and replacement of parts, minimizing downtime.

Maintenance and Longevity

Operational cost also depends on maintenance. Plants with durable components and accessible spare parts reduce repair expenses. Investing slightly more in a reliable plant saves substantial costs over time. Therefore, evaluating long-term serviceability is as important as initial price.

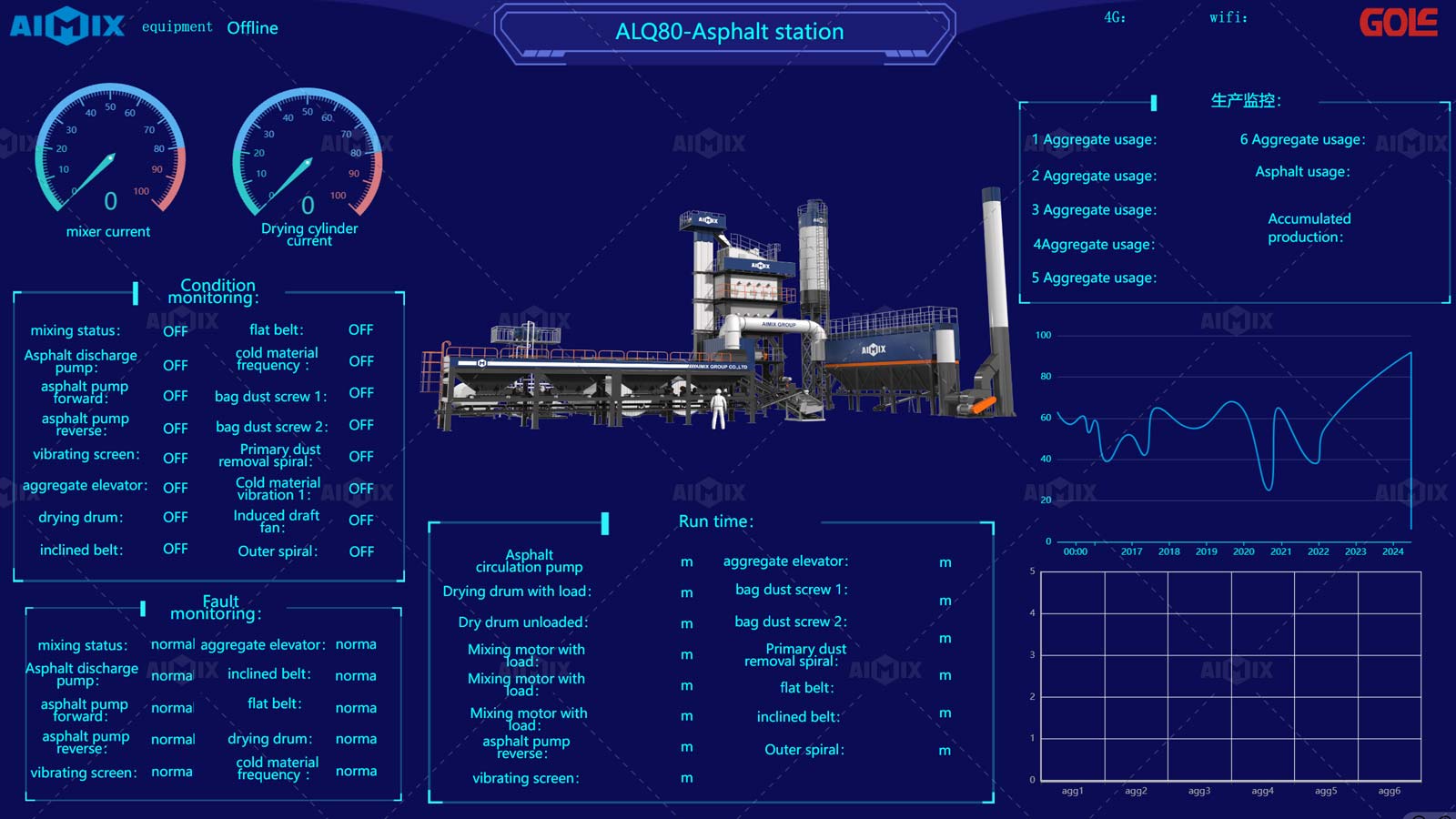

Automation and Digital Control

Modern asphalt plants feature automated control systems, enabling precise monitoring of temperature, aggregate ratios, and asphalt flow. Automation reduces errors and labor costs while improving consistency. In the long term, this increases both quality and profitability, especially for projects with strict performance standards.

Choosing the Most Cost-Effective Plant

For producing 1,000–2,000 tons per month, a compact drum mix or a small-to-medium batch plant often delivers the best cost-performance ratio. Consider the balance between upfront investment, operational costs, flexibility, and maintenance. Plants designed for low- to medium-capacity production are generally easier to transport, install, and operate, making them suitable for global deployment.

Final Recommendations

When selecting a plant, always align it with your project volume, energy efficiency goals, and quality requirements. Check the manufacturer’s reputation, support availability, and local service options. This approach ensures your asphalt production is not only cost-effective but also reliable and sustainable over time.

Conclusion: Maximize Value with the Right Asphalt Plant

Choosing the right asphalt mixer plant is crucial for both cost efficiency and operational success. For projects producing 1,000–2,000 tons monthly, carefully evaluate drum mix versus batch mix options, consider energy efficiency, and prioritize reliable service. By making an informed decision, you save money, reduce downtime, and maintain consistent asphalt quality.

At our company, we provide globally reliable asphalt mixer plants tailored to small and medium-scale production. With advanced automation, energy-efficient designs, and worldwide support, we, as an excellent asphalt mix plant supplier, help contractors maximize value while ensuring project success. Contact us today to find the most cost-effective asphalt solution for your projects.