Asphalt production in 2025 demands more than just capacity—it requires efficiency, sustainability, and cost control. For contractors operating 100–160 TPH asphalt mixing plants near me, energy savings have become a key factor in project success. Rising fuel costs, stricter emission regulations, and the need for faster return on investment are pushing plant owners to look deeper into how their equipment performs. So, what energy-efficient features really matter in this capacity range? Let’s explore five top features that make a real difference.

1. High-Efficiency Burner Systems

One of the largest energy consumers in an asphalt mixing plant is the burner. In 2025, modern 100–160 TPH hot mix plants come equipped with fully automatic, high-efficiency burners. These systems allow precise control of the fuel-air ratio, which helps reduce fuel waste and improve combustion efficiency.

Contractors working in remote areas or regions with limited fuel options can also benefit from dual-fuel burner designs. These burners support both diesel and heavy oil, giving flexibility and helping reduce fuel costs based on market prices. More efficient combustion doesn’t just save energy—it also lowers emissions, helping contractors meet environmental standards.

Why It Matters

For every 10% increase in burner efficiency, you can expect fuel savings of up to 7%. Over the lifecycle of a plant, this adds up to substantial cost reductions.

2. Intelligent Drying Drum Design

Transitioning from burner efficiency, another critical part is the drying drum. This component consumes a large amount of energy to remove moisture from aggregates. Energy-efficient asphalt plants feature optimized drum designs with better heat exchange rates and insulation layers that minimize heat loss.

Many 2025 models now include variable frequency drive (VFD) motors on drum rotation systems. These VFDs adjust speed based on actual moisture content and feed rate, avoiding unnecessary energy consumption during low-load operations.

Why It Matters

By reducing drum heat loss and optimizing aggregate flow, energy savings of 5–10% can be achieved without sacrificing output quality or speed.

3. Recycled Asphalt Integration (RAP Systems)

Beyond core hardware, energy efficiency extends to how asphalt is produced. Incorporating RAP—recycled asphalt pavement—into your mix reduces the need to heat virgin aggregates and bitumen. RAP preheating systems and batch mixing controls now allow up to 30% RAP usage in 100–160 TPH plants without performance loss.

Energy savings come from reduced burner operation and lower material processing. Moreover, this feature aligns with government green initiatives, often unlocking project eligibility or tax benefits.

Why It Matters

Every ton of RAP used can save up to 60% in energy compared to traditional asphalt production. This makes RAP systems a game-changer, especially in large-scale paving projects.

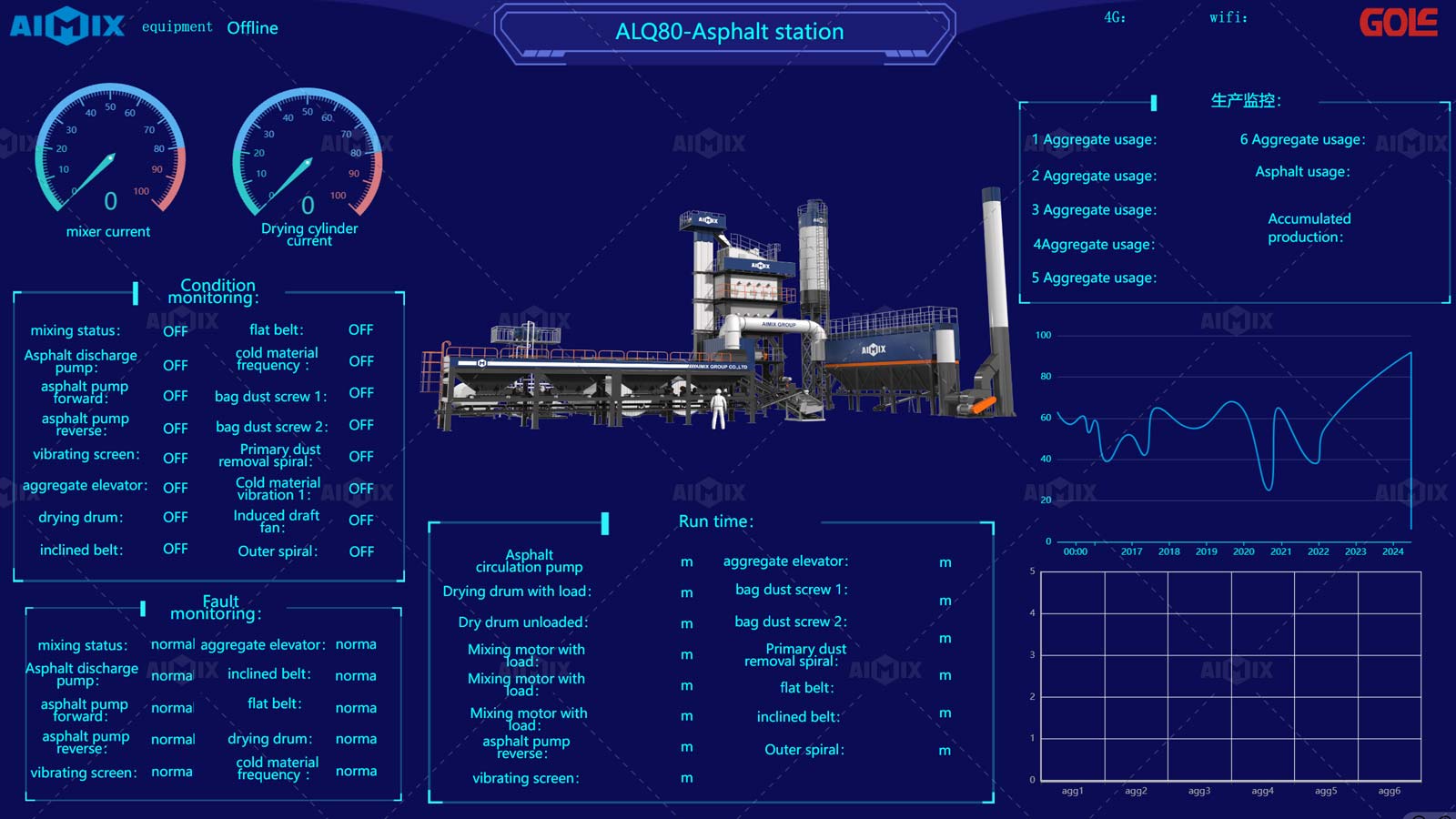

4. Smart Control Systems with Real-Time Monitoring

As we consider operational control, digital automation takes center stage. New asphalt plants in 2025 are equipped with smart PLC control systems that adjust energy use in real time. These systems monitor burner load, aggregate temperature, mixing time, and even fuel efficiency metrics during production.

Through an easy-to-use interface, operators can optimize performance and quickly react to changing conditions. This reduces idle time, prevents over-mixing, and avoids energy waste due to human error.

Why It Matters

Plants with smart control systems can reduce total energy use by 10–15%, especially during fluctuating production cycles or night operations.

5. Insulated Hot Aggregate Storage and Heat Recovery Systems

Rounding out the top five, we come to heat retention and reuse. Modern asphalt mixing plants now come with insulated storage bins and advanced heat recovery systems. The insulation helps maintain aggregate temperature longer, while heat recovery systems transfer excess heat from exhaust gases back into the drying drum or bitumen tank.

This not only cuts fuel consumption but also ensures mix temperature stability—critical for meeting paving quality standards, especially in remote job sites.

Why It Matters

Combining storage insulation and heat recovery can improve thermal efficiency by up to 20%, leading to direct savings in burner fuel.

Final Thoughts: Energy Efficiency Is No Longer Optional

Asphalt plant buyers in 2025 are no longer just looking at price tags or hourly output. Energy efficiency has become a deciding factor, influencing long-term profitability and compliance. Whether you’re bidding on government tenders, running private roadworks, or setting up a new plant in a remote island project—cutting energy costs while staying productive is key.

Choose a Plant That Supports Your Goals

If you’re looking for a 100–160 TPH asphalt plant that integrates all five of these energy-saving features, we’re here to help. At AIMIX, we, as one of outstanding asphalt mixing plant manufacturers, offer modern asphalt mixing plants tailored for the needs of Indonesian contractors. Each model is designed to minimize energy waste, reduce emissions, and increase reliability under real job site conditions.

Leave a Reply