As the global construction industry continues to evolve in 2025, the concrete mixer plant price is becoming a crucial consideration for contractors, developers, and ready-mix concrete suppliers. From urban infrastructure to real estate, the demand for reliable and cost-effective concrete batching solutions has skyrocketed. Understanding the factors influencing the price of concrete mixer plants, along with insights into the cement industry outlook, is essential for making strategic procurement decisions.

The Role of Concrete Mixer Plants in Construction

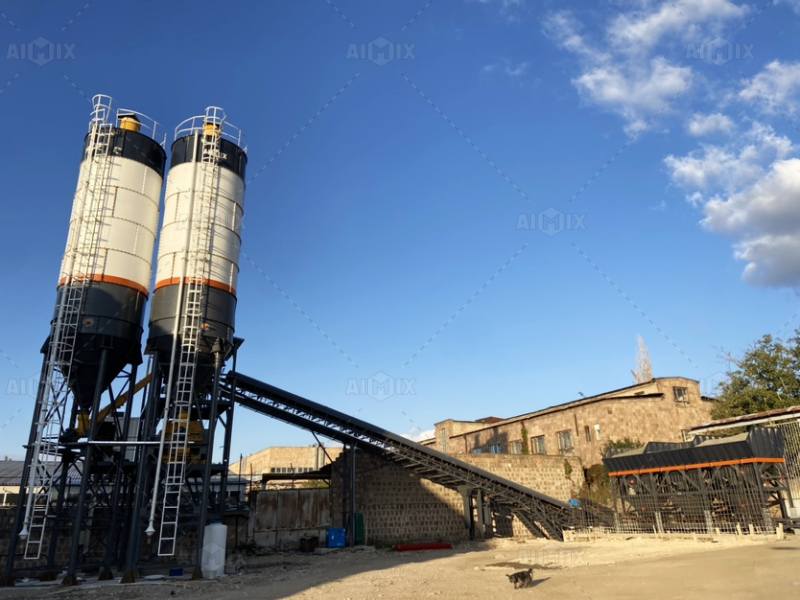

Concrete mixer plants, also known as RMC batching plants, are integral to producing high-quality ready-mixed concrete. These plants combine cement, aggregates, water, and additives in precise ratios, ensuring consistent quality and volume for various construction needs. They are widely used in highway construction, commercial building, residential development, and large infrastructure projects.

Depending on the type, capacity, and automation level, concrete mixer plant prices can vary significantly—from $25,000 for a small mobile batching plant to over $250,000 for a fully automatic, large-scale stationary plant.

Factors Influencing Concrete Mixer Plant Price in 2025

1. Capacity and Output Rate

One of the most direct factors affecting concrete mixer plant price is the plant’s capacity. Common capacities include:

-

AJ-35 / AJY-35 (35 m³/h)

-

AJ-60 / AJ-90 (60–90 m³/h)

-

AJ-120 / AJ-180 (120–180 m³/h)

Higher-capacity plants naturally command a higher price due to their greater production efficiency.

2. Automation and Control Systems

Fully automatic batching plants with PLC control systems are more expensive than semi-automatic or manual models. However, they offer reduced labor costs, better batching accuracy, and higher output stability—benefits that often outweigh the initial investment.

3. Type of Plant: Mobile vs Stationary

Mobile batching plants (like AJY-35 or AJY-60) offer flexibility and easy relocation, making them ideal for short-term or remote projects. These are usually more affordable upfront but may have a lower capacity. In contrast, stationary concrete mixer plants are designed for large, fixed-site operations and require higher setup costs, including foundations and installation.

4. Local Material and Labor Costs

Concrete mixer plant price also fluctuates with the cost of raw materials (steel, cement silos, motors) and labor in the country of manufacture or installation. In countries like India or China, local manufacturing often leads to more competitive pricing compared to plants sourced from Europe or the U.S.

Cement Industry Outlook in 2025 and Its Impact on Pricing

The cement industry is a critical driver of concrete plant demand. According to global industry forecasts, cement production is expected to grow at a CAGR of 3.8% in 2025, driven by:

-

Smart city projects

-

Public infrastructure expansion

-

Housing developments in emerging markets

-

Reconstruction projects in post-conflict and climate-affected areas

As cement demand grows, RMC batching plant prices are affected in several ways:

Raw Material Cost Surge

Cement prices continue to rise in regions facing energy price hikes or carbon taxes. This impacts concrete production costs and increases the operational cost of batching plants, especially in energy-intensive models.

Sustainability Regulations

Increased demand for eco-friendly construction is pushing manufacturers to offer plants with cement and water recycling systems, dust collection, and solar integration. These upgrades increase the concrete mixer plant price but are necessary to comply with environmental norms in the EU, Middle East, and parts of Asia.

Infrastructure Investment Trends

Countries like India, Indonesia, Saudi Arabia, and Nigeria are investing heavily in roads, bridges, and industrial zones. This fuels demand for large-capacity RMC batching plants, leading to higher prices due to increased orders and potential supply chain bottlenecks.

RMC Batching Plant Price: A Comparative Snapshot (2025)

Here’s a brief overview of typical RMC batching plant price ranges in 2025 based on type and capacity:

| Plant Type | Capacity | Price Range (USD) |

|---|---|---|

| Mini Mobile Plant | 25–35 m³/h | $25,000–$45,000 |

| Medium Stationary Plant | 60–90 m³/h | $60,000–$110,000 |

| High-Capacity Plant | 120–180 m³/h | $120,000–$250,000+ |

| Fully Automatic Models | All sizes | +$10,000–$30,000 extra |

Note: These are estimated FOB prices and exclude shipping, taxes, and foundation preparation.

Tips for Buyers in 2025

To make the most of your investment, here are a few key tips:

-

Compare multiple suppliers for technical features, warranty, and delivery timelines.

-

Ask for energy consumption data and spare part availability.

-

Choose a modular design if future capacity upgrades are anticipated.

-

Factor in installation and after-sales support, especially for complex stationary models.

Conclusion: Strategic Buying in a Growing Market

With cement demand growing and environmental standards tightening, the concrete mixer plant price in 2025 reflects more than just hardware—it reflects innovation, compliance, and long-term efficiency. Whether you’re investing in a mobile plant for a short-term road project or a high-capacity stationary plant for commercial batching, choosing the right model at the right price will define your project’s success.

If you’re evaluating your options and looking for the best value, reach out to trusted suppliers who offer transparent pricing and proven field performance. A well-chosen RMC batching plant is more than a machine—it’s a foundation for quality construction.

Leave a Reply